Our Products

Choose from a wide variety of high-quality, reliable Swagelok® components designed to provide lasting performance in your fluid system applications.

Categories

Fittings

Fittings

- Tube Fittings and Adapters

- Assembly-by-Torque Fittings (AbT)

- Cone and Thread Fittings

- Dielectric Fittings

- Flange Adapters

Valves

Valves

- Atomic Layer Deposition (ALD) Valves

- Ball and Quarter-Turn Plug Valves

- Bellows-Sealed Valves

- Check Valves

- Diaphragm-Sealed Valves

Regulators

Regulators

- Back-Pressure Regulators, Dome-Loaded

- Back-Pressure Regulators, Spring-Loaded

- High-Purity, High-Flow Gas Regulators, HF Series

- Pressure-Reducing Regulators, Dome-Loaded

- Pressure-Reducing Regulators, Spring-Loaded

Custom Fabrication for All Industries

Learn how Swagelok-trained specialists can save you time and improve your fluid system performance by designing and assembling systems for you.

Find the Support You NeedSwagelok Resources Curated for You

Field Engineering Q&A: How a Global Engineering Team is Making an Impact to Deliver Better Fluid and Sampling System Performance

Swagelok field engineers can help fluid and sampling system operators solve issues from leaks to sampling inaccuracy and everything in between. Here’s everything you need to know about Swagelok field engineering.

How to Improve Fluid System Performance

When fluid systems fail to perform safely and efficiently, plant productivity suffers. Swagelok can relieve the pressure of maintaining good system performance by providing expert guidance and helping to create a culture of continuous improvement.

Material Matters: Selecting the Right Material for Corrosion Resistance

An offshore platform can have nearly 50,000 feet of tubing, more than 20,000 fluid system components, no fewer than 10,000 fittings, and as many as 8,000 mechanical connections. No wonder choosing corrosion-resistant material isn’t easy. Learn how to make choices right for your application.

Maximizing the Life of Industrial Fluid System Components

The cost of replacing an industrial fluid system component goes beyond the price of the part. Learn how to lower system costs while maximizing the life of your components with preventive maintenance tips from the professionals at Swagelok.

Swagelok Products

We manufacture and supply a wide variety of products for use in industrial fluid system applications. Swagelok components and fluid system assemblies are used widely in the oil and gas, chemical and refining, transportation, semiconductor, and global construction industries.

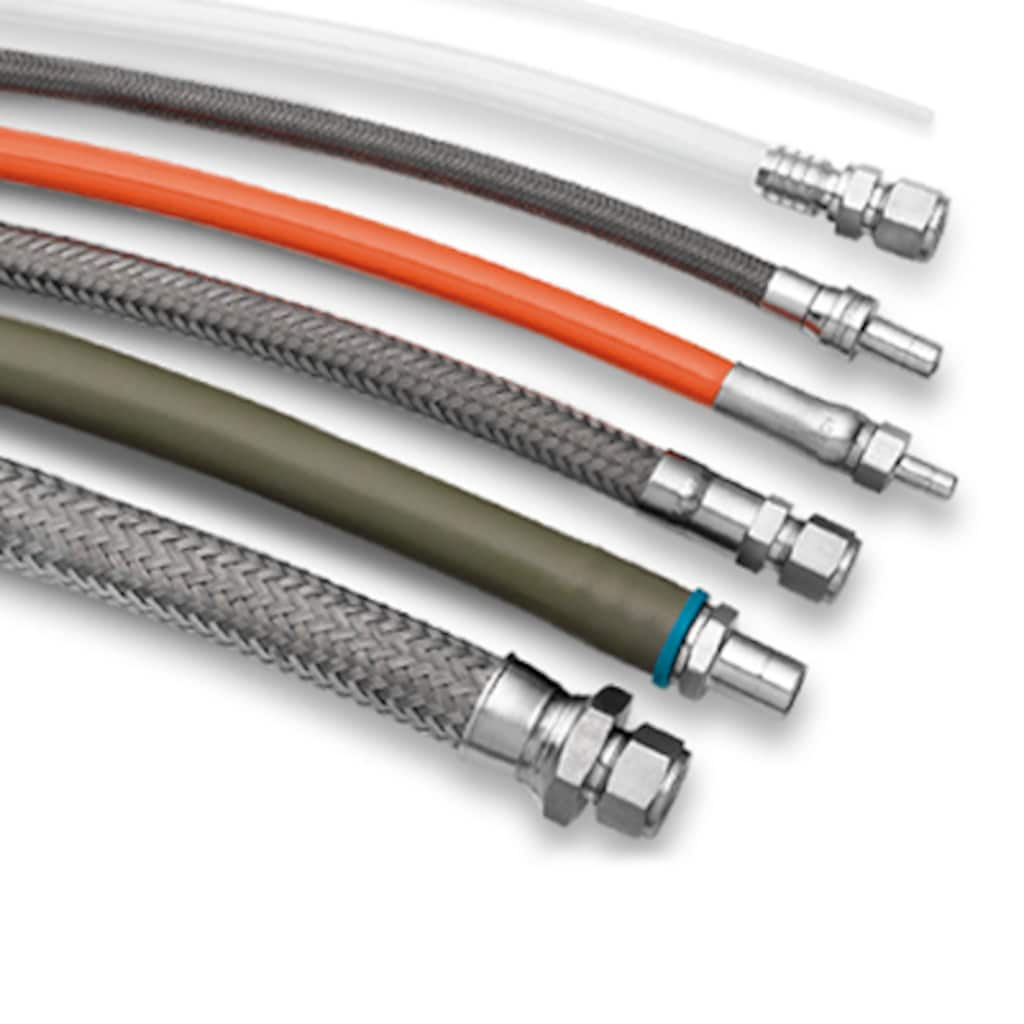

We offer high-quality fittings, valves, hoses, rigid and flexible tubing, tube accessories, pressure regulators, gauges and other measurement devices, filters, welding systems, leak detectors, lubricants, sealants, quick connects, mechanical seal support systems, grab sampling systems, sample cylinders, analytical subsystems, and miniature modular systems.

Our products are designed to stand up to the demands of challenging operating environments worldwide, are thoroughly tested, and are backed by the Swagelok Limited Lifetime Warranty.