How to Make the Most of Your Fluid Systems, Part I

Part one of a three-part series on how to maximize the performance of the fluid systems in your facility

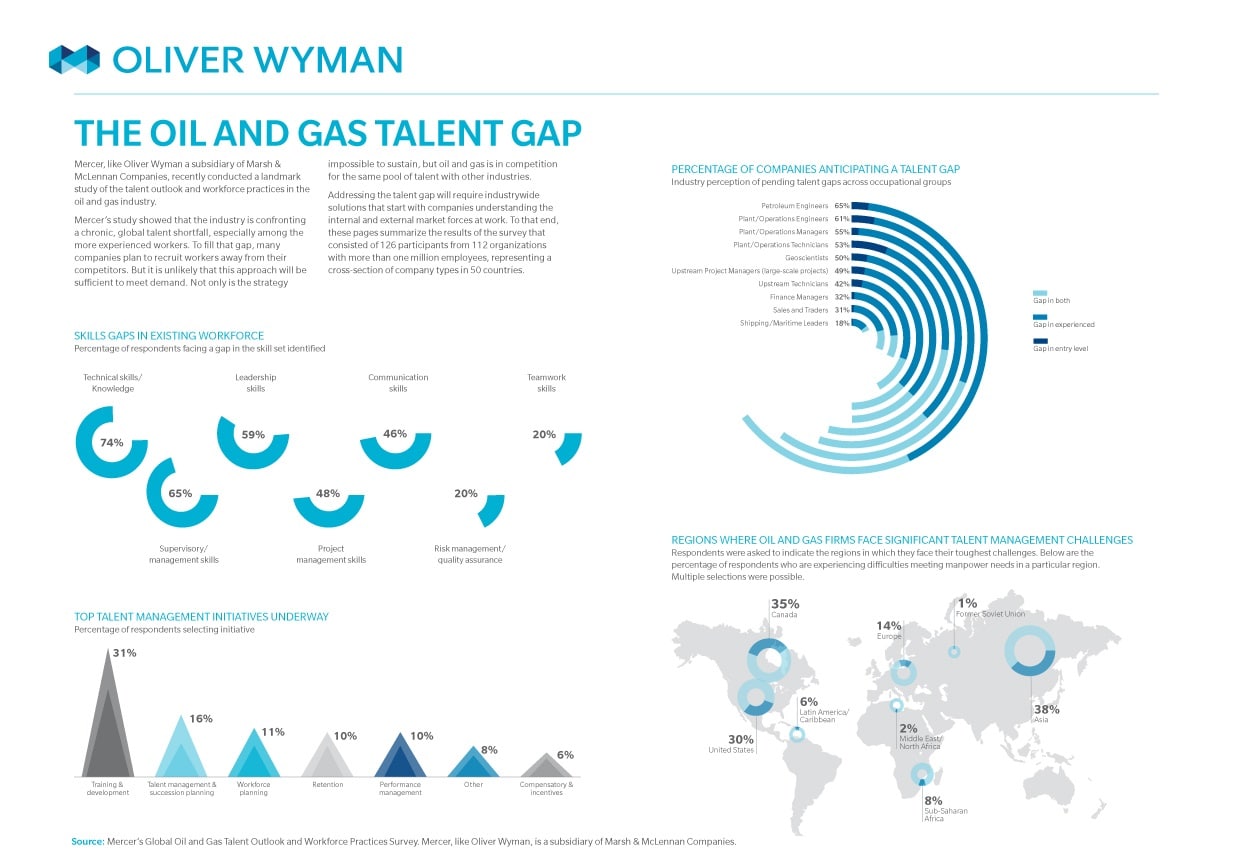

The internet is full of stories about the "silver tsunami" and high retirement rates for baby boomers across the United States. This phenomenon creates pressure for employers like you. Low unemployment means that holes in your workforce may take longer to fill, and gaps in expertise as your most dedicated workers retire. For example, the 2014 infographic below shows that 74% of oil and gas organizations around the world are facing a gap in technical skills and knowledge. 65% see less management skills and 59% see a lack of leadership skills, and this skills gap affects the safety and performance of these facilities.

Every high-performing facility requires a strong team. No matter how strong your team is, gaps in staffing and experience can create dangerous decisions and situations over time. Maybe inexperienced workers installed hose with kinks. Intermixed fittings could be causing leaks in crucial areas of your plant. Someone got overzealous with tubing, purchasing thick-walled tubing that limits flow, and then installed it on unsupported runs. You can’t do it all on your own, and you need your team to know the right components for the job.

The only constant in this world is change, and there are a few strategies that you can try to better prepare your business for the change that's coming in the near future.

Create a Plan

Over 40% of the workforce is expected to retire in the next decade. The generation that came after the boomers, Generation X, is a much smaller group, so many new hires are Millennials. Millennials often get a bad rap in the media, but they are also praised for their innovative habits and ideas. You and many of your colleagues and competitors are starting to see a wide gap between your most seasoned workers and the younger, less experienced millennials that make up most of the current workforce. Take a look at your current team and consider what it will look like in five years. Who will leave the biggest holes when they go? What do they bring to the team? Who is pulling more than their weight? Think about what you can do to replace those skills.

Succession plans are typical for upper management roles. Apply this kind of big picture thinking across all the different roles in your facility. Who is the right person to replace the person you have in each role now? What do they bring to the role that’s unique? What are other ways to do that job better? When you take a closer look, you may find a new strategy for allocating resources, a new management structure, or innovative options to increase efficiency and safety in your business.

Technology is Key

What younger employees may lack in expertise they make up in competitive insights. The youngest generation grew up immersed in the rapid-fire advances of technology, so they are more fluent in tech tools that can make your team more responsive and efficient. Millennials are often quick to learn and more flexible in their habits, so they’ll be more open to trying a tool like Slack for better communication on-site or using Google Sheets to update shared team spreadsheets online.

As technologies in your industry change, these workers will not only keep up, they will help you stay ahead of the curve. With the right foundation you can develop your youngest workers into leaders that will help your business continue to expand while trimming costs and inefficiencies.

Invest in Training

Many of your long-time loyal workers learned their craft over a long and dedicated period of time. You can’t replace their instincts, but you can save yourself from the trial and error they experienced while learning on the job. Consider asking your seasoned employees to mentor the newest workers. This can be a valuable way to pass on tribal knowledge. Keep in mind though, teaching isn’t something we are all gifted with. Teaching is a specific skillset, and your business will feel the impact of incomplete or inconsistent training down the line.

Make basic and advanced training a required part of your new hire and onboarding processes. Training will guarantee a foundational set of skills for your whole team. It will also give your workers a shared language that will make them stronger together. Training is an investment in your business, and it will help bridge the different levels of understanding and experience on your staff. Training isn’t much time and money when you consider the rewards you get in the long run from the added expertise of your workforce.

You’ve worked hard for your success, and you have the power to extend your legacy for generations to come. What is the most cost-effective way to address gaps in staffing and experience? Make a plan for your facility today.

Want to read more? Check out Part II.