How to Select the Right Hose for Your Application

Hoses' greatest advantage is its flexibility. When you need tubing to change direction, you have to bend it or put an adapter elbow on it. That can affect flow rates and increase pressure drop. These added components also add to the overall cost. A PTFE hose with a similar pressure capability may eliminate the need for joints and elbows. In a jet airliner, PTFE is likely to be the major fuel line. In the event of an accident, a flexible fuel line won't crack and cause a fire hazard.

Flexible hose lets you easily deal with an offset between any two elements of your system. As caulk is to a carpenter, hoses are to fluid system designers and installers.

PTFE is also tough. It's corrosion resistant and easily cleaned. If you don't physically abuse it, it can last for decades. It also doesn't conduct heat as readily as stainless steel tubing, giving you an extra measure of insulation.

There are several important considerations when you are selecting the right hose for your application.

- Hose Core

- Hose Reinforcement

- Hose Cover

- Hose End Connections

Hose core

The hose core is the most important layer. You can select between come in metal, silicone, nylon, fluoropolymers and various kinds of rubber hoses. Whatever core material you select comes into direct contact with your system fluids, so the materials must be compatible. Primary considerations are chemical compatibility, fluid temperature range, permeability, and maintenance and cleaning of the hose in your application.

Hose reinforcement

Hose reinforcement takes into consideration the stress your application will put on the hose. What kind of pressure will it be dealing with? Does it need to twist or bend? What kind of weight will your hose have on it? We make a range of hose reinforcements with materials that are compatible with different fluids and applications. Be sure to select carefully.

Hose cover

The hose cover protects your hose from kinking, abrasion, permeation, and extreme temperatures. Hose cover options include:

- Armor Guard

- Fire Jacket

- Nanogel Cover

- Spiral Guard

- Spring Guard

- Thermosleeve

Stainless steel Armor Guard covers offer flexible protection against hose damage from the movement of gas cylinders. It protects the hose in applications that might put a crushing force on the hose. The strength of steel protects the entire length of the hose from kinking without impairing hose flexibility.

Fire Jacket covers are woven fiberglass coated with silicone rubber. This material protects and insulates the hose from internal temperature extremes. It guards against molten splashes and flames, and helps resist hydraulic or lubricating oils.

Nano-Gel Cover protects hose from freeze-ups in cryogenic service.

Add Spiral Guard covers made from helical plastic to hoses already in service. This cover is a quick way to add flexible protection from abrasion. You can add it to the entire hose, or just to the ends.

Spring Guard is highly flexible and made from helical stainless steel. It helps your hose resist kinking and abrasion. You can add Spring Guard hose cover to the ends or to the entire hose.

Thermosleeve is a braided fiberglass cover saturated with a synthetic coating. This cover prevents direct contact with the hose, protecting users handling this hose in high-temperatures. It also protects the hose from weld splatter, ultraviolet light, and abrasion.

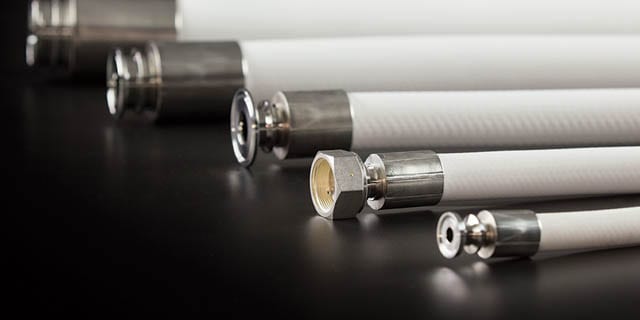

Hose End Connections

Be sure to pick a hose that eliminates the need for adapters to make your hose easy to install and maintain. Consider industry standards and system specs while you are making this important decision.

Swagelok can put almost any type of connection on the end of our flagship PTFE hose. We use a crimping process rather than swaging, which used to be the standard. During assembly we use a circumference compression die with eight segments. The die compresses the ferrule to the end connection, preventing pull-off. This also allows the hose to maintain its pressure rating because it results in less deformation of the hose compared than swaging. At Swagelok, each hose has its own crimp specification. We test them to ensure that we maintain the proper inside diameter.

Swagelok has also created a hose pocket guide to answer all your hose questions in detail. Contact us to request a hose pocket guide.