Tech Talk: Regulator Basics

Everything You Need to Know About Regulator Basics

When I think about regulators, I think back to something that our field engineer, Matt Hasenohr, said:

"95% of the returns that we get for regulators are either at the beginning or end of their life." Matt Hasenohr, Regional Field Engineer at Swagelok Northwest (US)

As Matt hinted, it's critical to focus on a regulator at the beginning. Focusing on the design, installation, and ensuring it's used for the proper application can extend its life and avoid troublesome fluid system problems.

While regulators are critical to quality fluid systems, they don't need to be complicated. Whether you're experiencing inconsistent control pressure, lack of Flow, plugging, or even damage to the internal components nailing down regulator best practices, in the beginning, will go a long way in terms of fluid system productivity.

Learn the basics in Our Tech Talk Regulator Basics Webinar:

Matt and Adam breakdown the ins and outs of all things regulator basics.

This guide is designed to do just that. Nail down the basics. Upon reading this blog post, you'll have a deeper understanding of:

- What regulators are

- Regulator theory

- Regulator performance criteria (Lockup, choked Flow, droop, supply pressure effect)

- Addressing performance criteria

Let's get started with an important question.

What Are Regulators?A pressure regulator is a fluid system component designed to control pressure under a given set of system conditions. There are two types of pressure regulators:

Pressure regulators control only pressure; they do not control fluid Flow. |

Two Types of Pressure Regulators

Pressure-reducing regulators (more common of the two) control pressure to the process by sensing outlet pressure. They control their own downstream or outlet pressure. On the other hand, back-pressure regulators control pressure from the process by sensing the inlet pressure. They control their own upstream or inlet pressure.

Pressure-Reducing Regulators

Back-Pressure Regulators

Both types of pressure regulators operate under similar principles and utilize similar components.

Shop Regulators

Swagelok Northwest (US) offers a variety of different types of regulators for industrial fluid systems.

Browse Pressure Reducing Regulators

The right combination of pressure reducing regulators to fit practically any situation.

Browse Back Pressure Regulators

Back pressure regulators that provide reliable control for your fluid systems.

Basic Regulator Theory

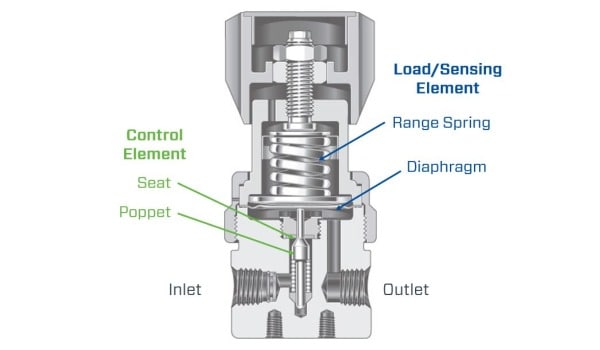

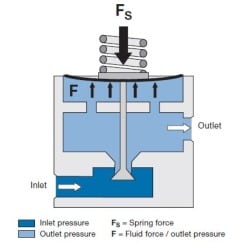

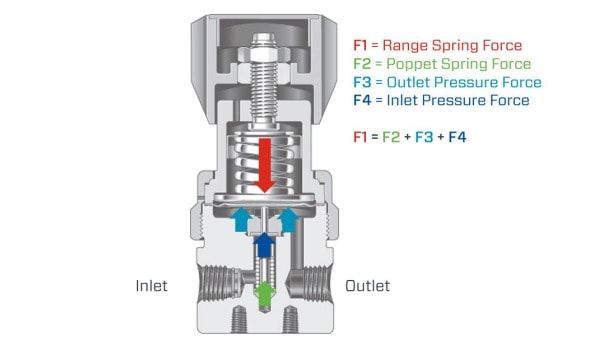

Dive deeper into the inner workings of a regulator, and you'll find the control element and load/sensing element working together to control pressure within the system. Both consist of four main components working in concert:

- The control element controls flow and pressure via the seat and poppet. Think of it as the valve within the regulator.

- The load and sensing element is made up of a range spring and diaphragm.

Operating Principle - Balance of Forces

We like to break down how a regulator works into a basic balance of forces equation. Similar to a mathematical formula. We have the range spring force that we're controlling, and there's also the poppet spring force, the outlet pressure force, and the inlet pressure force. Breaking down the balance of forces can give you insight into why and how some of the regulator performance criteria function the way that they do.

Performance Criteria

Now that you've learned some basic regulator theory, the next step in optimizing regulators is to know what to look for in pressure regulator performance criteria. Key quality indicators include: Lockup, Choked Flow, Droop, and the Supply Pressure Effect. Let's dive in.

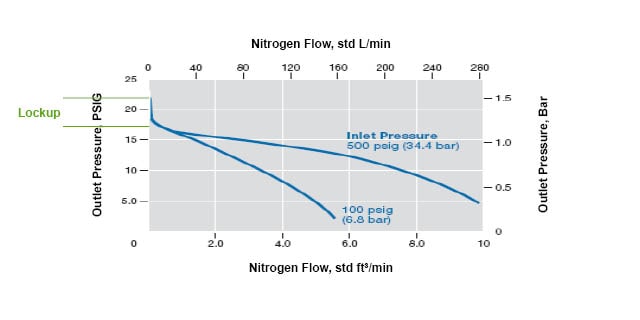

What is Lockup?

The first criteria we're going to cover is Lockup. It occurs at the beginning of the flow curve and is the difference in pressure between a flowing and now-flowing condition. When Lockup occurs, you'll see a relatively big spike in outlet pressure. See the flow chart example below for reference:

How Do We Address It?

This one is a little bit tricky. You may ask yourself: when shutting off the Flow, why is there a slight increase in pressure when going from a flowing state into a non-flowing state? Imagine a group of people running through a hallway towards an open door, but then the door suddenly closes, people are going to slam up against each other, pressure builds until a point of failure. Now imagine that scenario as a fluid system. The valve suddenly shuts, pressure begins to build, molecules coming closer together, the regulator doesn't have a way to relieve that. Ultimately, the poppet spring closes the seat, which traps some of that pressure downstream. To address this issue:

- Start by understanding how Lockup may impact your system.

- Keep the regulator going and operating within the optimal flow range (between the Lockup and the Choked Flow).

- Use a softer seat material. When ordering regulators, you can choose softer seats to reduce Lockup.

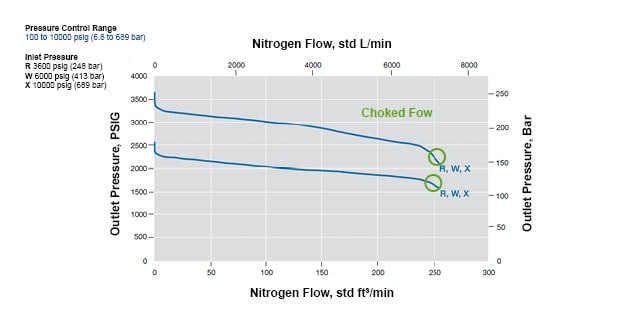

What is Choked Flow?

The second criteria on the other side of our control range is Choked Flow. Choked Flow occurs when a regulator is in the fully open position and no longer regulates. It acts as a restricting orifice, and it will not be able to control pressure. See the flow chart example below for reference:

How Do We Address It?

When dealing with Choked Flow, proper regulator selection is at the forefront of importance. Things to consider before selection are:

- What are the flow requirements?

- What's our flow rate range going to be?

- What's our maximum flow rate?

It's safe to say selecting the proper regulator for your system is critical to avoiding Choked Flow. But what if you have a regulator installed that is experiencing this? Simply reduce the flow rate, adjust your pressure, and get your regulator back into the optimal flow range.

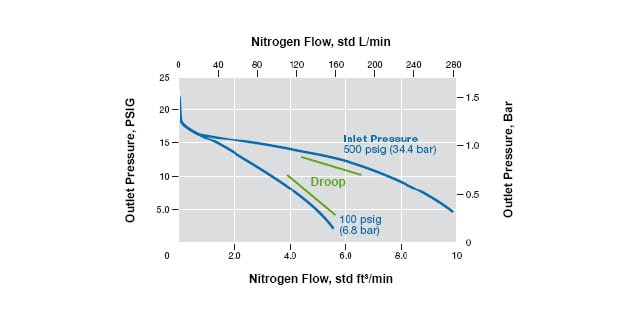

What is Droop?

Droop is the change in outlet pressure as our flow rate changes. Essentially the increased flow results in the set spring extending, which loosens the load force. Droop is primarily caused by the set spring. The result is because of the lower load force, and we have a reduced outlet pressure. See the flow chart example below for reference:

How Do We Address It?

How do we address droop? If your flow rate is consistent, you shouldn't be concerned. However, if you want your regulator to handle a range of different flow rates, you'll want to do the following:

- Adjust the regulator - set the regulator to a static state, turn on flow, then adjust.

- Regulator selection - "flatten the curve," longer spring or a lower spring rate will equal less droop. Another option to consider is to use a dome-loaded regulator, which applies pressure to the dome rather than a spring which means less droop.

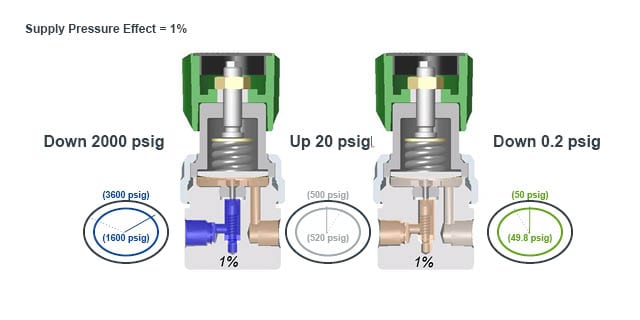

Breaking Down Supply Pressure Effect

The supply pressure effect, also referred to as inlet dependency, is defined as the change in outlet pressure due to a change in the inlet, or supply, pressure. Under this phenomenon, inlet and outlet pressure changes are inversely proportional to each other. If the inlet pressure decreases, there will be a corresponding outlet pressure increase. Conversely, if the inlet pressure increases, the outlet pressure decreases.

The manufacturer typically provides a regulator's supply pressure effect. SPE is usually depicted as a ratio or percentage describing the change in outlet pressure per change in inlet pressure. For example, if a regulator is described as having a 1:100 or 1% SPE, for every 100 psi drop in inlet pressure, the outlet pressure will increase by 1 psi.

How Do We Address It?

- Address the supply pressure effect by adjusting the regulator as inlet pressure changes.

- Select a regulator that has a limited supply pressure effect, such as a two-stage regulator (see below) or one with a balanced poppet design.

Whew! That's a lot to take in. Let's recap the important takeaways:

- Regulators are fluid system components designed to control pressure under a given set of conditions.

- There are two types of pressure regulators: Pressure reducing regulators and back pressure regulators.

- A regulator consists of four main components working in concert: Seat, poppet, range spring, and diaphragm.

- Eliminate troublesome performance issues like Lockup, Choked Flow, and Droop with proper regulator selection at the beginning.

- Limit supply pressure effect by adjusting the regulator as inlet pressure changes or using a two-staged regulator approach.

If you are struggling with optimizing your fluid system, beyond regulator selection, turn to your local field engineering team for help. We can come on site, identify issues, and troubleshoot problems.