Mechanical Seal Support Systems

Mechanical Seal Support Systems

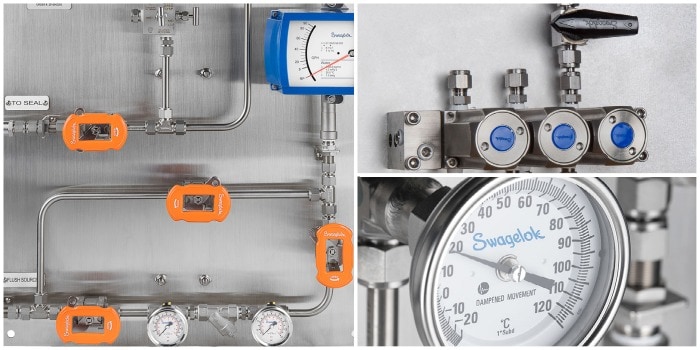

Swagelok seal support systems are designed to support a specific mechanical seal and set of process conditions. These systems supply either gas or liquid to the mechanical seal to regulate the seal's environment. These systems are configurable for single, dual, gas delivery, and offer high-performance for your operations.

Ensuring your seal support system is appropriately designed and installed is critical to keep your rotating equipment available for production. If seal system fluid is dirty or contains particulate, seal life can be negatively affected. Similarly, delivering the fluid at the wrong pressure or temperature can cause premature or even catastrophic seal failure.

Optimal System Design According to API 682

Swagelok Northwest (US) offers mechanical seal support system as kits and assemblies that are easy to install and are backed by The Swagelok Limited Lifetime Warranty. Our seal support systems are available in various American Petroleum Institute (API) plan configurations and are assembled according to industry best practices.

Swagelok mechanical seal support kits and assemblies feature standard designs that include the minimum arrangement of components as specified by API 682. We avoid pipe threads and limit the number of connections wherever possible, minimizing potential for costly leaks.

Seal Plan Kits and Assemblies

Process Side Plans

Plans include: API Plan 11, API Plan 12, API Plan 13, API Plan 14, API Plan 21, API Plan 22, API Plan 23, API Plan 31, API Plan 41

Between Seal Plans

Plans include: API Plan 52, API Plan 53A, API Plan 53B, API Plan 53C, API Plan 54, API Plan 55, API Plan 72, API Plan 74, API Plan 75, API Plan 76, API Plan 72/76

Avoid Downtime with Fluid Systems Built to Last

Seal plan kits are a collection of components used to connect the seal support plan to the pump. Each kit contains everything needed for proper installation, including an engineered drawing, making it simple to standardize how plans are connected to the pump during turnarounds or other projects. Kits also adhere to API best practices by showing technicians where to bend tubing to eliminate potential leak points through the reduction of elbow fittings and pipe threads.

To explore how Swagelok-built mechanical seal support kits and assemblies can help you avoid unplanned downtime, reduce the probability of leaks, simplify maintenance, and maximize the life of your rotating equipment, reach out to your local fluid system experts!