Supporting the Clean Energy Industry

Supporting the Global Movement Toward Green Energy

We support the evolution of hydrogen as a clean energy source and enable alternative-fuel vehicles to run on hydrogen and liquified natural gas (LNG) and compressed natural gas (CNG). From the lab to the field, we support global customers in safely and efficiently reaching their goals for clean energy production, distribution, compression, refueling, and mobility applications.

Minimizing Downtime, Maximizing Reliability

Whether you are building on-vehicle, fueling, refueling station, or in-facility fluid systems, you need access to readily available, reliable fluid system components to keep your assembly lines and critical processes moving. We offer support through more than 200 authorized sales and service center locations across 70 countries. Here, local Swagelok-trained and certified associates can provide you with conveniently accessible, globally consistent fluid system products suited for clean energy industry applications. They can also provide onsite assistance to help you troubleshoot and avoid fluid system leaks, inefficiency, or downtime.

- Choose from components such as our assembly-by-torque (AbT) or FK series medium-pressure fittings designed for reliability, ease of installation, remake, and visual inspection so you can quickly assemble complex systems safely and reliably.

- Work with Swagelok-certified local associates who design ready-to-integrate, fully engineered fluid system assemblies configured to perform reliably in your applications, maximizing the service life of your equipment while minimizing the risk of leaks. They also reduce the burden on your employees who can spend less time assembling and maintaining fluid systems.

- Our field service specialists can evaluate your fluid systems and deliver prioritized recommendations to improve your overall system reliability, improving uptime and safety in the process.

Enabling Performance

Designing hydrogen and CNG/LNG fluid system solutions is uniquely challenging. Hydrogen embrittles and degrades many metals, and its small molecule size can lead to leaks if seals are not tight enough. High pressures, rapidly changing temperatures, and persistent vibration all pose challenges to alternative fuel vehicle fuel systems and supporting infrastructure. Our engineers worldwide can help you find the advanced fluid system performance you need by recommending or constructing fluid system components and assemblies configured to suit your requirements.

- Our standardized, configurable fluid system assemblies are thoroughly tested, inspected, packaged, warrantied, and easy to order with single part numbers. Allow your team members to focus their attention on more pressing tasks than designing and assembling systems by choosing fluid system assemblies built according to best practices through our Custom Solutions program.

- Our experienced product design engineers have the technical knowledge, advanced software, and manufacturing expertise to customize fluid system products to meet demanding specifications. They can help with applications such as fuel line integration, priority panels, dispensing systems, heavy-duty refueling boxes, and much more.

- Our materials scientists can apply an expert-level understanding of metallurgy and chemical compatibility to help you find the right materials and designs for challenging applications. Minimize corrosion, hydrogen embrittlement, and other issues by working with specialists to choose fluid system components that have all the appropriate certifications, approvals, and compositions to work well in demanding applications.

Improving Safety

Safety is a high priority in any application involving the handling and transportation of potentially hazardous fluids. It is especially important when the future of alternative fuel vehicle adoption depends on widespread perceptions that the technology is safe to use. We can help you build safety into your fluid system-related practices, from component installation through routine maintenance. We provide:

- High-quality Swagelok components and assemblies engineered and tested to keep you safe to operate and maintain throughout their lifecycles, as well as leak-tight fluid system assemblies designed according to best practices for operator safety.

- A comprehensive program of fluid system training programs designed to help new and experienced team members and contractors work more safely by improving their fluid system design, installation, inspection, operation, and maintenance capabilities.

- Evaluation and advisory services that help you address risk factors throughout your fluid systems such as fluid leaks caused by the improper component installation or product selection, inefficient system designs, or selection of materials unsuited for alternative fuel applications.

Understanding Regulatory Compliance

It is not enough to have access to reliable fluid system components—you also need suppliers that understand the processes, certifications, and other requirements that are unique to the clean energy market. Swagelok products are certified for use by relevant industry organizations around the world allowing you to feel confident knowing that Swagelok solutions will meet your performance criteria and comply with governing mandates. We can help you navigate:

Regional Compliance Needs

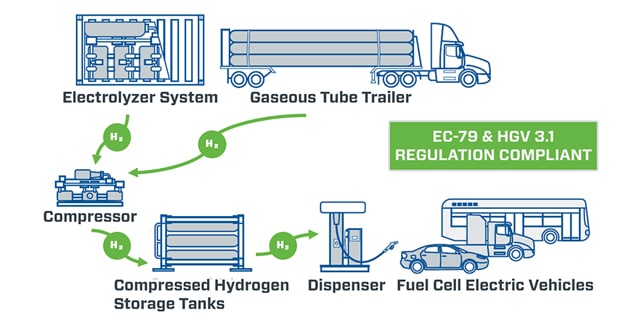

We work with regional standards organizations to understand complex engineering requirements, and we provide a variety of certified products for on-vehicle and infrastructure use to help you stay compliant wherever you operate. These include EC-79 and HGV 3.1 compliant products for hydrogen systems and NGV4.X compliant products for dispensing systems, among other certifications.

Production Parts Approval Processes (PPAP)

We develop components specifically for clean energy industry use, offering standard products up to Level 3 of PPAP. We can work with you to ensure the solutions you choose will meet specifications.

International Material Data System (IMDS) Requirements

We understand IMDS protocols, and we can help you more easily fill out elements of construction documents that show you meet environmental regulatory requirements.

Technical Cleanliness Requirements

We can draw from our comprehensive portfolio of high-purity fluid system products and strict manufacturing controls to help you achieve the levels of cleanliness you need in demanding applications.

Manufacturing Emissions Compliance

Our field engineering team is highly trained and ready to come to your facility to help identify potential leak points in your systems and suggest leak-tight, compliant components that are low-emissions certified to help you avoid fugitive emission-related fines and reputation damage.

Bringing Clean Energy to the Marketplace

Clean Energy Services

Swagelok Northwest (US) has the expertise to help you compete in a performance-driven, safety-focused emerging market.

Hydrogen Solutions

We support the fast-growing hydrogen energy industry with fluid system solutions.